Environment and energy

One of our core competences, the grinding of worn tools is a contribution to the protection of the environment. The effort to produce new tools is avoided for as long as possible. Exact wear analysis of the tools reduces tool removal to what is absolutely necessary. This significantly allows for more grinding cycles and also protects the environment.

High investments

We have invested heavily in renovations that benefit the indoor and indoor climate as well as the environment.

Of course, optimal air conditions contribute to worker protection by ensuring a healthy and modern work environment for employees. But they are also crucial for the product quality of the produced cutting tools and their output.

We are energy self-sufficient in heating and cooling.

The measures range from the modernisation of the entire ventilation system, air purification and recovery of heat from production to heating with BIO mass. The cooling of the production hall is also CO² neutral due to cold water from the in-house well.

Resource recovery

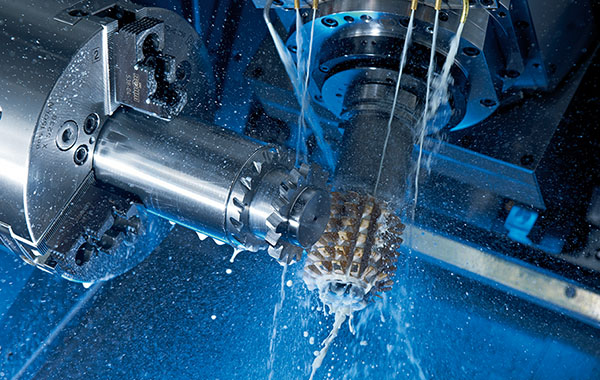

The sludge from the grinding processes is separated, into hard metal and HSS, and used to recover valuable crude materials.